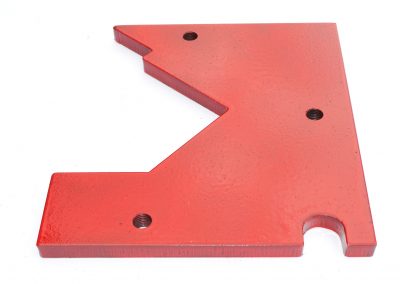

Liner Plates

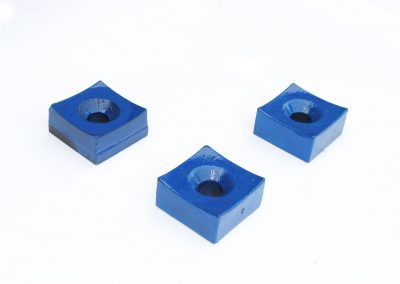

At GES, our core expertise is in the manufacturing and supply of liner plates, cheek plates and hopper plates. These plates are used predominately for crushing and screening equipment. We ship in excess of 150tonne per month of machined wear plate in 400BRN, 450BRN & 500BRN. Over the years, we have have invested significantly in equipment and tooling that is specified to machine this level of toughness. GES only use the best tried and trusted suppliers of wear-resistant steel, offering excellent consistency, above average hardness and superior surface quality.

All of our production is carried out in-house, from producing AutoCAD DXF drawings if required, to nesting, plasma cutting, folding, drilling, tapping, countersinking, edge chamfering, deburring, welding, paint priming, and shrink wrapping. We are capable of shipping orders ranging from single items to containers anywhere in the world at the most competitive freight prices due to our expansive network of couriers and freight forwarders.

GES has access to 300tonne of material stock holding available within 24 hours to greatly improve your time-to-market. We stock material from 6mm to 75mm with sheet sizes 6mtr x 2.5mts and 4mts x 2mts. Material outside of this range can also be supplied.

Here at GES, we understand the importance of getting the wear parts to the customer as soon as possible, which is why we allocate additional production slots each day for urgent ‘machine down’ turnarounds. This allows us to ship parts the day that they are ordered, thus allowing our customers to recommence their production with minimal to no down time.

Our efficient production capabilities, coupled with our vast quantity of steel allows us to offer extremely competitive prices to our customers whether locally or thousands of miles away.